Multi Slot Stator Insulation Machine , Slot Insulation Machine OEM / ODM

-

Highlight

electric motor winding equipment

,paper inserter

,Multi Slot Stator Insulation Machine

-

NameStator Insulation Paper Inserting Machine Slot Insulation Inserting Machine

-

ModelSC160

-

Stator I.D.70-140mm

-

Stator O.D.≤160mm

-

Material's Thickness≤0.35mm

-

Machine Dimension(L)1150*(W)1000*(H)1600mm

-

Processing TypePaper Folding Machine

-

Place of OriginChina

-

Brand NameSMT

-

CertificationISO/SGS Audit

-

Model NumberSMT-CB160

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsInner preservative film,outer regeneration plywood case package suitable for air and sea transportation, effective for protecting the goods,1*20' GP could load 10 machine packages

-

Delivery Time58 - 76 days

-

Payment TermsT/T, L/C

-

Supply Ability1pcs / 58 - 63 days

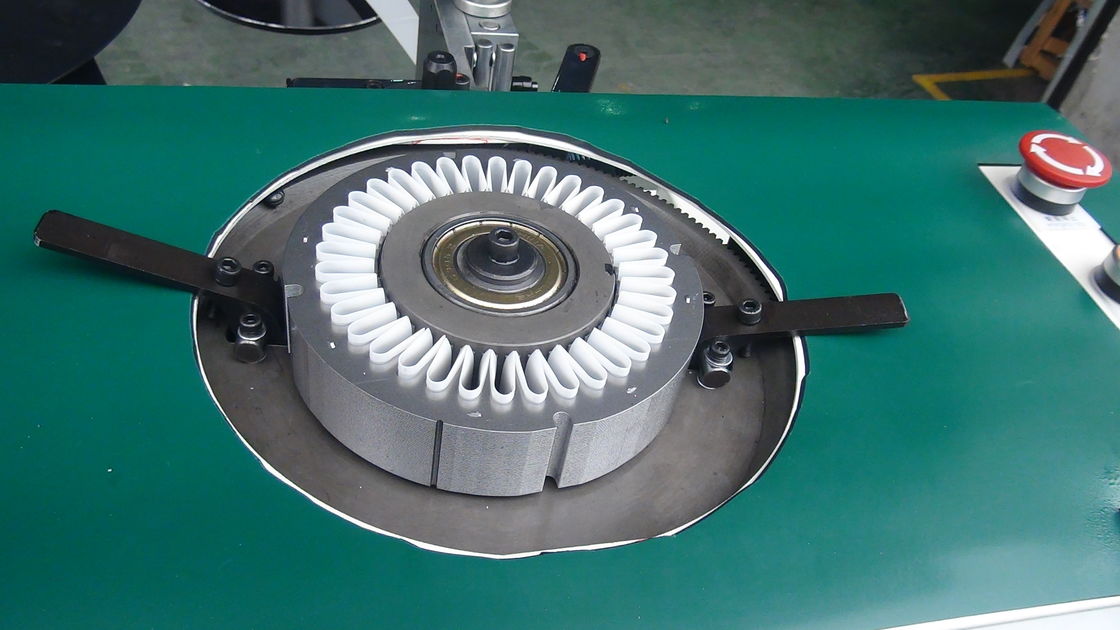

Multi Slot Stator Insulation Machine , Slot Insulation Machine OEM / ODM

Multi - Pole Stator Slot Insulation Machine SMT - SC160 PLC Programme Control

This slot insulation paper inserting machine is a special design specific to different design or different sizes of slot; can finish insulation paper insertion at a time; automatic adjustment to perimeter, automatic cutting paper, automatic hemming and automatic inserting when inserting to various or different-sized slot; use servo paper inserting machine to feed paper and settle breadth; interpersonal interface sets required specific parameter; forming mode is adjustable to different sizes of slot automatically; characterized by simple operation, low noise, fast speed and high automaticity.

(1) Main Technical Data

| Model | SC160 |

| Stator I.D. | 70-140mm |

| Stator O.D. | ≤200mm |

| Stack Height of Stator | ≤160mm |

| Width of Edge Folded | 3-7mm |

| Feeding Perimeter | ≥15mm |

| Material's thickness | ≤0.35mm |

| Power Supply | 380V/50/60Hz 0.75Kw |

| Air Pressure | ≥0.6MPa |

| Machine dimension | (L)1150*(W)1000*(H)1600mm |

(2) Application

1. Suitable exclusively for large and medium-sized motors,inserting insulation paper automatically from bottom of stator slot;

2. Automatic paper feeding,edge folding and forming;

3. Characterized by low noise, fast speed, excellent forming,etc;

4. Slot number change is controlled by electric;

5. Interval slot inserting and skip slot inserting could be at option;

6. It is convenient and easy for different slot number stator production and changing tooling;

7. Especially suitable for generator,deep pump motor, three phase machine,etc.

(3) Machine Main Characteristic

It is a special design specific to different design or different sizes of slot; can finish insulation paper insertion at a time; automatic adjustment to perimeter, automatic cutting paper, automatic hemming and automatic inserting when inserting to various or different-sized slot; use servo paper inserting machine to feed paper and settle breadth; interpersonal interface sets required specific parameter; forming mould is adjustable to different sizes of slot automatically; characterized by simple operation, low noise, fast speed and high automaticity.

The equipment adopts programmable terminal, also called touched screen, that can set and display necessary information, it is easy to operate and reliable.

![]()

(4) OEM/ODM

Innovational technical team provides perfect complete technical solutions, to satisfy every customer’s unique requirement;

Specialized after-sale team and engineers offer superior quality, rapid after-sale service door to door, to solve customer’s all after-sale problems;

Wide spreaded domestic after-sale service service network stations and overseas agencies ensure of powerful after-sale service;

Multi communication methods and full time customer service personnel dispel customer’s after-sale scruples 24 hours.

(5) Production Line Profile

With good service, professional team and reliable quality, Nide provide customer with different kinds of AC motor, DC motor,BLDC motor manufacturing technical consulting service and Turn-key projecting service, including the motor cost evaluation, manufacturing know-how, staff training,and complete turn-key project.