Automatic Horizontal Semi - Auto Winding Inserting Machine 380V 50HZ / 60HZ

-

Highlight

automatic motor winding machine

,motor winding equipment

-

NameSubmersible Pump Motor Coil Inserting Machine

-

ModelSMT-QX600

-

Stator I.D.110-210mm

-

Stator O.D.≤260mm

-

Dimension(L)2650×(W)820×(H)1100mm

-

Weight900kg

-

Core Length≤250mm

-

Slot Number Range24-48 Slots

-

Place of OriginChina

-

Brand NameSMT

-

CertificationISO / SGS Audit

-

Model NumberSMT-QX600

-

Minimum Order Quantity1pcs

-

PriceNegotiable

-

Packaging DetailsPlywood Box With Sealing.

-

Delivery Time8 - 14 weeks

-

Payment TermsT/T, L/C

-

Supply Ability1pcs / 7 - 13 weeks

Automatic Horizontal Semi - Auto Winding Inserting Machine 380V 50HZ / 60HZ

Well pump motor stator coil and wedge winding insertion machine

Automatic Horizontal type Big power long stack length pump stator coil middle forming

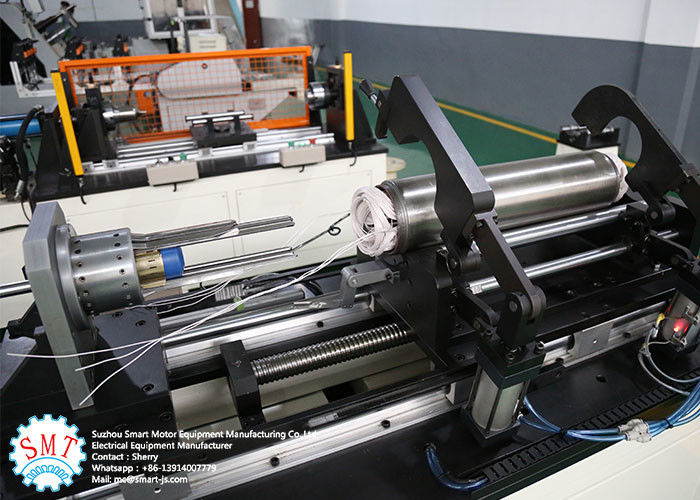

This is horizontal type semi-auto winding inserting machine. It adopts Mitsubishi AC servo motor and pneumatic element system drive. It si controlled by PLC and equipped with X and Y spindle auto feeding device. It can automatically insert coil and wedge into stator slot simultaneously.

1. Main technical data

Pump Motor Stator Automatic Assembly Machines / Submersible Pump Motor Coil Inserting Machine

| Stator Stack length | 300~600mm |

| Stator OD | Max 300mm |

| Stator ID | 50~150mm |

| Wire diameter | 0.18~1.2mm |

| Voltage | 380V/50/60HZ |

| Power | 3.5Kw |

| Weight | about 1200kg |

| Dimension | L2100*W2000*1600mm |

2. Application

It is applied to deep water pump motor and other various type of overlength motor stator.

Information needed for stator winding insertion machine inquiry:

It wil l be better if customer could send us detailed drawing including below information.

1. Stator lamination drawing

2. Stator stack drawing

3. Winding drawing

4. Winding distribution drawing

5. Wedge drawing

6. Other technical requirement.

If possible, it will better if customer could send us samples.

3. Competitive advantages

Variety of application, easy operation.

We have Overseas Service Center.

Machine is controlled by PLC.All the parameter can be set in the touch screen.

It is suitable forstators withdifferent modelnumber and dimension.

The operation and tooling change process is easy.

We could customize machine for our customer as per their requirement.

We directly supply our machines to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

The coil inserting prcoess is the most important process in the manufacture of a stator for an electric motor. The coil insertion tool is the key part of coil inserting machine. In order to keep the coil inserting smoothly, we design and manufacture various kinds of insertion tools with absolutely high quality, well resistent.

This machine conducts gang control to inserting main shaft, wedge paper feeding shaft and wedge magazine indexing shaft through PLC control system assembly, cooperating with intelligent human-machine communication system. It conducts enamelled wires insertion, slot wedge cutting and moulding, also the wedges insertion into the stator slots when coil insertion, which completes the single/multi phase coil insertion and slot wedge insertion at one step. The machine has the advantages of even wire push torque, stable moulding of slot wedge, high production efficiency, low cost, easy and reliable use and maintenance.

![]()

4 OEM/ODM

Innovational technical team provides perfect complete technical solutions, to satisfy every customer’s unique requirement;

Specialized after-sale team and engineers offer superior quality, rapid after-sale service door to door, to solve customer’s all after-sale problems;

Wide spreaded domestic after-sale service service network stations and overseas agencies ensure of powerful after-sale service;

Multi communication methods and full time customer service personnel dispel customer’s after-sale scruples 24 hours.

5. Production Line Profile

With good service, professional team and reliable quality, SMT provide customer with different kinds of AC motor, DC motor,BLDC motor manufacturing technical consulting service and Turn-key projecting service, including the motor cost evaluation, manufacturing know-how, staff training,and complete turn-key project.

6. About Us

Suzhou Smart motor Equipment Manufacturing Co.,Ltd is one of the high-tech key enterprises which specialize in designing, producing and selling motor manufacturing equipments in China. The company now has nearly 150 employees, including more than 30 engineers and technicians, with the building area about 20,000 square meters and a hundred sets of advanced production and test equipments. It is now qualified for designing and manufacturing full production line (starts from coil winding to final forming of a stator) for AC motors such as home appliance motor, industrial medium and small motors, pump motor, rolling door motor and automobile motor etc. In 2012, SMT passed the certification of ISO9001:2000 Quality Management System.