-

Highlight

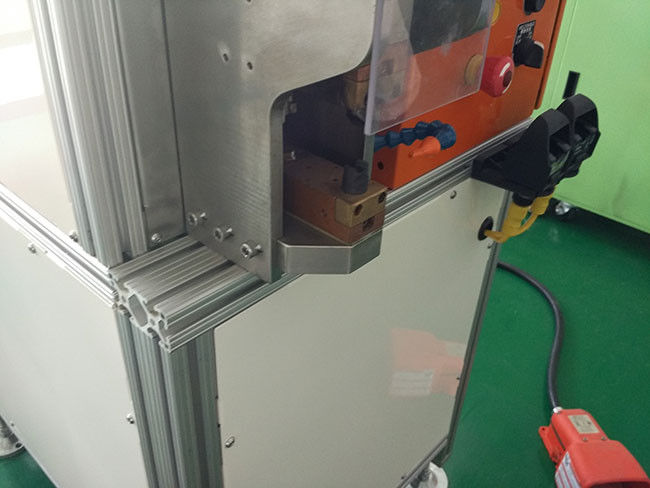

Metal Welding Machine

,Commutator Fusing Machine

-

NameAutomatic Commutator Welding Machine For Fusing Commutator

-

Model NumberK3220

-

Power Supply400VAC, 50 Hz – 60 Amp

-

Min.Temperature15°C

-

Weight960Kg

-

ColorOrange

-

Place of OriginChina

-

Brand NameSMT

-

CertificationISO / SGS Audit

-

Model NumberSMT- K3220

-

Minimum Order Quantity1pcs

-

PriceNegotiable

-

Packaging DetailsPacked with vacuum film in plywood case. Or, we can do it as your order.

-

Delivery Time42 - 78 days

-

Payment TermsT/T, L/C

-

Supply Ability1pcs / 42 - 78 days

50Hz – 60HZ Amp Automatic Fusing Machine For Fusing Commutator

50Hz – 60HZ Amp Automatic Fusing Machine For Fusing Commutator

1. Feeding method: automatic feeding. Loading and unloading

2. Parameter setting: touch screen and power parameter setting

3. Power control method: current feedback, high precision countercurrent

4. Commutator type: both hook type and raise type

5. Wire diameter 0.1mm-1.2mm

6 Armature OD. φ10mm-φ50mm

7. Shaft OD: φ5mm-φ15mm

8. Commutator O.D.: φ15mm-φ40mm

9. Commutator slot/hook number: ≤36

10. current range: 0.5-50KA

11. Voltage range: 0.1-9.99V

12. Power range: 1.00-99.99KW

(1) Product General Information

| Brand Name: | SMT |

| Model Number: | K3220 |

| Certification: | SGS/ISO9001 |

| Place of Origin: | China |

| Product Name | Stator Lead Wire Tube Fusing Machine | Application | Electric motor stator production |

| Status | New | Paint | On request |

| Warranty time | One year after machine(s) arrive in customer’s plant | Service | Overseas service center available |

(2) Description

1.Machine, electrical cabinet and disconnect mounted to aluminum extrusion table.

2.Heavy duty construction utilizing SMT K-Head design.

3.SMT machine enamel paint unless otherwise quoted.

4.20 kva water cooled transformer.

5.400VAC, 50 Hz – 60 Amp input required.

7.Control of squeeze time (prior to fuse), upslope time, fuse time, fuse current, cool time, repeats, hold time and force of head during fuse.

8.Capability to store and recall up to fifty (50) different fuse schedules.

(3) Patented Tube Fusing Technology

In tube fusing, traditional connectors are made redundant by a simple and inexpensive tube which captures the wires to be connected. Resistively heated fusing electrodes apply the necessary pressure and heat to the tube/wire bundle to make a reliable connection. These machines are versatile for most any application including fusing magnet wires, Litz.wire and/or insulated leads within a tube terminal.

(4) Eliminate Stripping and Brazing

This patented technology eliminates the need for an operator to strip the magnet wire from the leads prior to fusing the lead bundle. Capable of fusing up to 150*18AWG(1.0mm) wires in parallel, the heat of the fusing operation burns off the wire enamel while the tin from the tube cleans the area to be connected. The force of the head combined with the controlled heating of the electrode creates a reliable connection while minimizing manual operations.

(5) Thermal Crimp Fusing Technology

With the patented thermal crimp technology, the connector is automatically made from a strip of tinned copper material. This connector is then presented to the operator for placement of the magnet wire and/or lead wire. Once fused, excess wire is trimmed from the connector resulting in the smallest possible package with the highest quality connection.

(6) About Us

Suzhou Smart motor Equipment Manufacturing Co.,Ltd is one of the high-tech key enterprises which specialize in designing, producing and selling motor manufacturing equipments in China. The company now has nearly 150 employees, including more than 30 engineers and technicians, with the building area about 20,000 square meters and a hundred sets of advanced production and test equipments. It is now qualified for designing and manufacturing full production line (starts from coil winding to final forming of a stator) for AC motors such as home appliance motor, industrial medium and small motors, pump motor, rolling door motor and automobile motor etc. In 2012, SMT passed the certification of ISO9001:2000 Quality Management System.

![]()